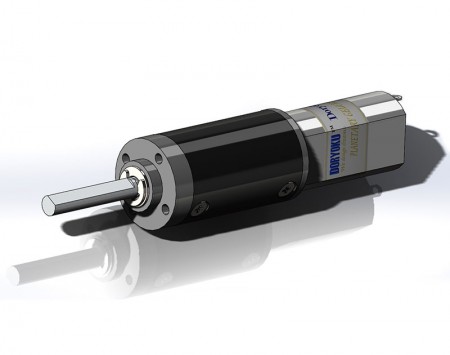

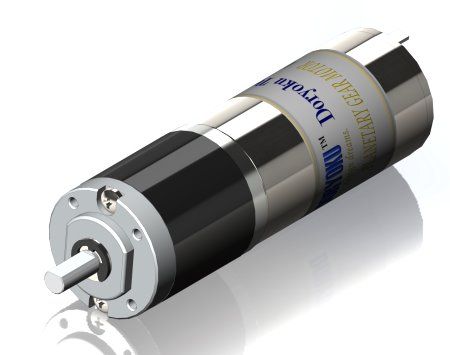

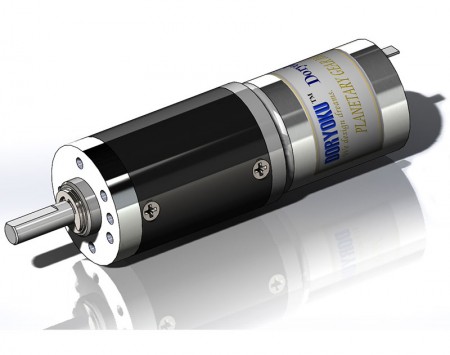

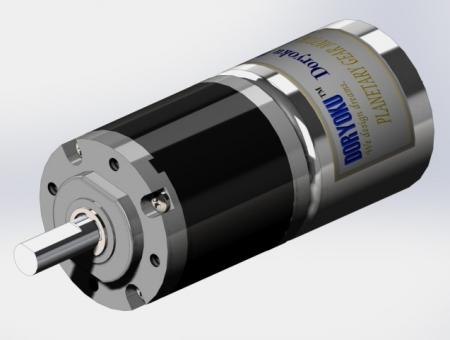

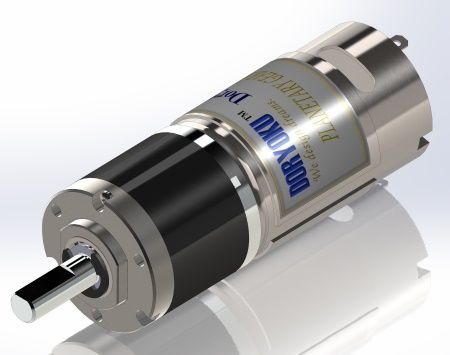

DC Planetary Gear Motor

High torque high efficiency

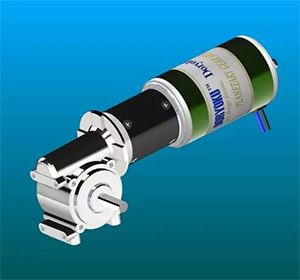

Planetary Reducers also named Epicyclic gearing Reducers –There is a significant increase on Planetary Gear Motor usage and customer like planetary geared motor to design their equipment more and more. They choose Planetary reducers to combine with dc gear motor, brushed motor, brushless motor, stepping motor and servo motor.

Planetary geared motor could work on high operating efficiency, easier mountings, offer high torque in a compact package, wide range of reduction ratio for wide applications. Especially it’s ideal for intermittent or continuous duty heavy situation.

The size of DORYOKU Planetary Gearbox range from 18mm to 124mm; gear ratios ranging from 4:1 to 11909:1, and continuous torque of up to 800 kg-cm!

Optical encoder, Magnetic encoder, brake could be installed according to your request.

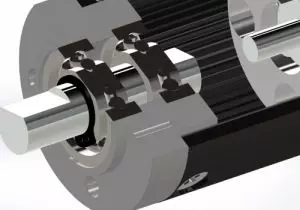

Dual Bearings Design

Dual roller bearings design and heat treatment of gear or shaft to increase the strength of gearbox or thicken the gear to let bearing capacity bigger. We do our best to meet customers’ critical request.

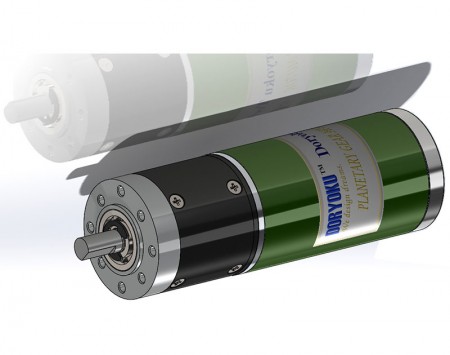

Planetary gearbox structure

Planetary geared motor is highly reliable. The efficiency of 1 stage is about 90%, 2 stages is about 81%, and so forth. The structure makes it ideal for many applications – from industrial automation to medical.

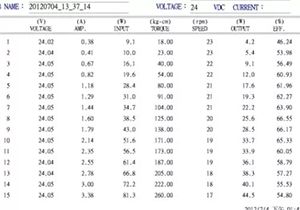

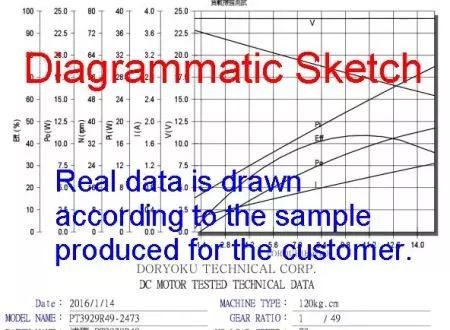

DATASHEET

We could offer a datasheet of straight speed-torque curve, with starting torque, speeds and current to let you know the motor’s peak efficiency with operating torque.

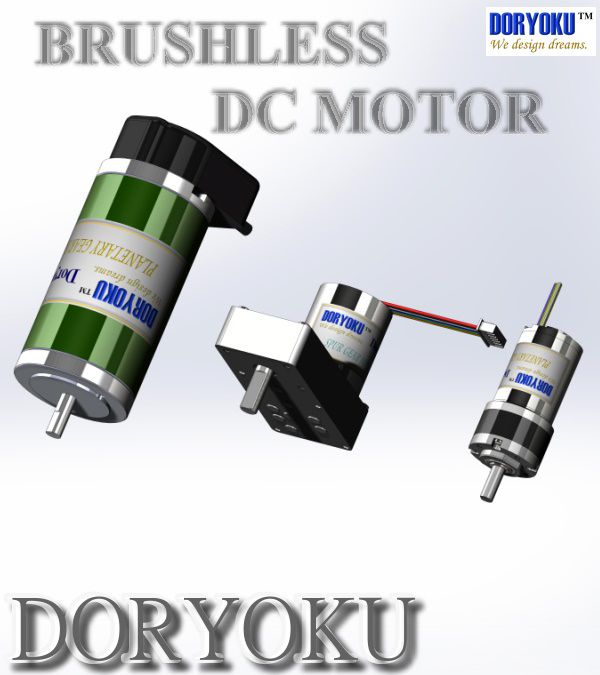

Features

- 6VDC, 12VDC, 24VDC, 36VDC

- 1RPM-5000 RPM

- High torque DC gear motor, DC brushed motor could be selected and combine.

- Optical encoder, Magnetic encoder, encoder+brake Option

- Performance Curves of Torque, Current, Speed will be attached as sample request.

DIA18 Micro Planetary

P18 Micro Planet

Diameter 18mm, Quiet Brushed DC Motor With Planetary Gearbox, Continuous torque stable. We believe...

DetailsDIA22 Mini tube Motor

P22B Planet BEARING

Diameter 22mm, Quiet and long life special design Brushed DC Motor with Planetary Gearbox makes...

DetailsDC Planetary Gear Motor

P22LB Long Planet

Diameter 22mm, Quiet and long life special design Brushed DC Motor with Planetary Gearbox makes...

DetailsDIA24-L66-80 STRONG DC Planetary Gear Motor

P24 STRONG Planet

Diameter 24mm, strong design Brushed DC Motor with Planetary Gearbox makes Continuous torque...

DetailsDIA26 Low Noise DC Planetary Gear Motor

P26 Mini Planet

Diameter 26mm, Quiet and long life special design Brushed DC Motor with Planetary Gearbox makes...

DetailsDIA26 Strong tube motor

P26-1 Strong

Quiet Brushed DC Motor With Planetary Gearbox, Continuous torque stable. Best choice for high...

DetailsDIA32 Low Noise Planet motor

P32 Low current

Quiet Brushed DC Motor With Planetary Gearbox, Continuous torque stable. Best choice for high...

DetailsDIA37 Low Noise Planet motor

P35 Low current

Quiet Brushed DC Motor With Planetary Gearbox, Continuous torque stable.Best choice for high...

DetailsDIA37 Quiet Planet motor

P35-1 short GearMotor

A brushed DC motor from DORYOKU is ideal for portable and small devices. Best choice for high...

DetailsDIA37 Strong Vr. Planet motor

P35-2 Strong

Strong Brushed DC Motor With Planetary Gearbox, Continuous torque stable. Best choice for high...

DetailsDIA43 Servo motor Gearbox

P43C-1 Servo Planetary

DORYOKU GEAR Motors custom fractional PMDC gear motors are ideal for wide range of OEM applications.

DetailsDIA43 DC Strong Planetary Geared

P43C Strong Planetary

Quiet Brushed DC Motor With Planetary Gearbox, Continuous torque stable. Best choice for high...

DetailsDC Planetary Gear Motor - High torque high efficiency | High Torque Worm Gear Motors Manufacturer Since 2000 | Doryoku Technical Corp.

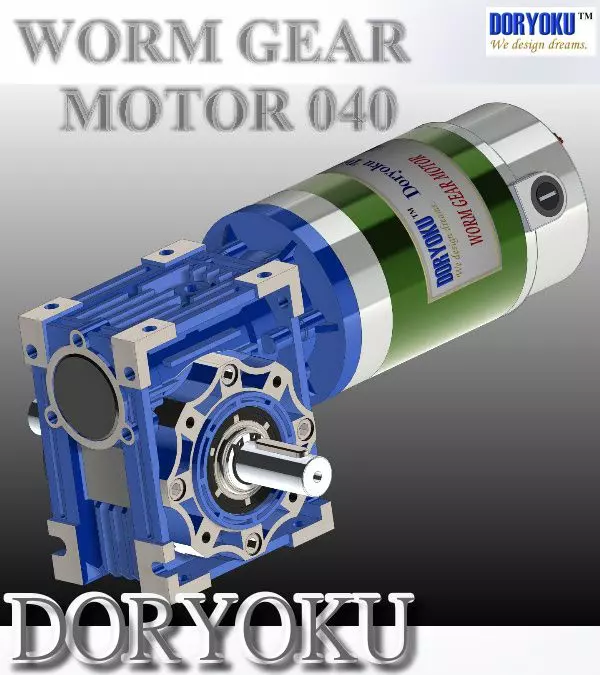

Based in Taiwan since 2000, Doryoku Technical Corp. is a DC gear motor manufacturer. Their main products, including DC Planetary Gear Motor, DC Planetary Gear Motors, Worm Gear Motors, Spur Gear Motors, which can be brushed, BLDC, stepping, NEMA, brushless, or with servo motors combined.

DORYOKU is one of the leading DC servo motor | DC gear motor manufacturers since 2000 based in Taiwan, and is specialized in producing high torque dc motor to meet the needs of automation applications. Our DC gear motor such as, planetary gear motor, DC servo motor, brushless DC motor are designed with size range from 18mm to 80mm, gear ratios ranging from 4:1 to 11909:1. and continuous torque of up to 4,166 oz-in! We offer a cost-effective solution for your automation requirements. The product line includes planetary, Worm, spur Gearbox, combined with brushed, BLDC, stepping, servo motor.

Doryoku Tech. has been offering customers high torque DC motors and DC gear motors, both with advanced technology and 25 years of experience, Doryoku Tech. ensures each customer's demands are met.